Description

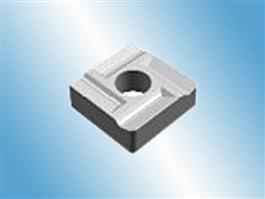

Tungsten carbide cutting blades are basically categorized into carbide inserts with holes and carbide inserts without holes. The code name of the ones with holes consists of form, basic parameter and flute profile, while the code name of carbide inserts without holes comprises of form and basic parameter. We not only produce standard tungsten carbide turning inserts, but also customize tungsten carbide cutting blades according to clients’ requirements. Our company has our own factory and is able to mass produce within a given time. Tongyi mainly supplies four types of tungsten carbide turning inserts, including 3-A/3-C/3-D/3-N, T3-A/T3-D/T3-F, 4-A/4-D/4-H/C-H and X3-8/X3-11/X4-0/X4-8/X4-11/XC types.

Applications

Tungsten carbide cutting blades are used in mining, construction, tunnel, oil and gas, forestry and agriculture industries. They can also be used for rough and semi-finishing of carbon steel and alloy steel (including forged steel parts, stamped parts and cast iron surfaces) during intermittent cutting.

Features

1. Our tungsten carbide turning inserts are featured with high hardness, high corrosion resistance and high heat resistance.

2. Our tungsten carbide cutting blades are manufactured from the finest grade carbide as well as from a special carbide grade carefully selected by us based on our customers’ requirements. We can also research and develop more suitable formula according to the use conditions.

3. We are able to make tungsten carbide turning inserts in both standard and custom configurations at reasonable prices. For non-standard parts, we are capable to make molds by ourselves and produce them as per your requirements.

4. Our company has been certified by ISO 9001:2008. All our tungsten carbide cutting blades are made under strict quality control to ensure the consistent quality.

5. We also provide samples and quotations of tungsten carbide turning inserts if required. Fast delivery is promised.

Classification

1. 3-A/3-C/3-D/3-N Tungsten Carbide Cutting Blade

It is generally designed to cut hardwood flooring, cast iron, stainless steel, fiberglass materials, ceramic tile, stone, plaster, etc. Different grades of inserts are suitable for cutting different materials.

2. T3-A/T3-D/T3-F Tungsten Carbide Cutting Blade

These tungsten carbide turning inserts are driven by a high power motor and high-torque gear reduction unit or an AC vector drive. During the cutting process, the metal is released in a shearing action by the teeth as the insert turns and the feed mechanism moves the blade forward.

3. 4-A/4-D/4-H/C-H Tungsten Carbide Cutting Blade

These tungsten carbide turning inserts are broadly used to cut metal and non-metal materials. Because of their hardness, wear resistance and heat resistance, they are recognized by many users. They can be made in both standard and custom configurations.

4. X3-8/ X3-11/ X4-0/ X4-8/ X4-11/XC Tungsten Carbide Cutting Blade

They are well appreciated by our clients for their sturdy construction and durability. They are manufactured using superior grade components and raw materials that are procured from the best providers of the industry. We are able to design and produce tungsten carbide turning inserts of different configurations and also provide custom products.

Establish in 2002, Zhuzhou Tongyi Industry is a professional manufacturer of tungsten carbide products in China. We design and produce a full range of carbide products, including tungsten carbide drill bits, carbide anvils, carbide rods, carbide blanks, carbide drawing dies, carbide nozzles, tungsten carbide cutting blades, etc. Our products have been exported to many countries, such as Vietnam, Indonesia, the United States, Poland, Russia, Ukraine, etc. We provide custom services to our clients. All of our products can be customized for special purposes.