Description

4-A/4-D/4-H/C-H tungsten carbide inserts are broadly used by manufacturers to cut metal and non-metal materials. Because of their hardness, wear resistance and heat resistance, they are recognized by many users. We provide a full range of carbide turning blades which can be made in both standard and custom configurations.

Applications

Tungsten carbide inserts are suitable for cutting aluminum and nonferrous alloys. They are essentially used for cutting tough alloys, such as cobalt, nickel, zirconium and titanium based metal with extremely good surface finish.

Advantages of Tungsten Carbide Turning Blade

1. Longer durability is a typical advantage.

2. We are able to offer a full range of tungsten carbide inserts. They are developed using the modern machines and advanced technology in order to ensure the quality in accordance with ISO standards.

3. Higher cutting rates can be achieved in cutting stainless steel, high alloy and tool steels.

4. A wide range of carbide turning blades are available in stock at market leading rates.

5. Special backing material of our tungsten carbide inserts increases fatigue resistance at high cutting speed.

6. We also provide custom service to meet client’s specific needs. Samples and quotations are available if needed. Fast delivery is promised.

Technical Parameters

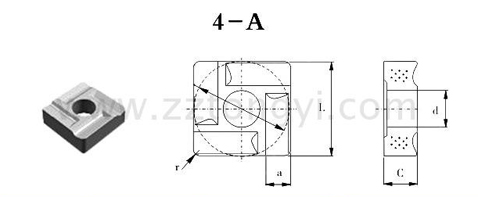

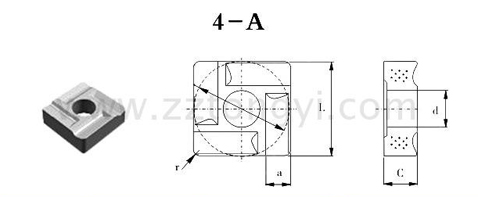

4-A

|

Model

|

Dimension

|

|

Right

|

Left

|

D=L

|

C±0.13

|

D±0.13

|

r

|

a≈

|

|

41005A

|

41005AZ

|

10±0.08

|

3.5

|

4.2

|

0.5

|

2.4

|

|

41305A

|

41305AZ

|

13±0.13

|

4.5

|

5.2

|

0.5

|

3.4

|

|

41315A

|

41315AZ

|

13±0.13

|

4.5

|

5.2

|

1.5

|

3.4

|

|

416105A

|

416105AZ

|

16±0.18

|

5.5

|

6.2

|

0.5

|

4.0

|

|

41610A5

|

41610A5Z

|

16±0.18

|

5.5

|

62

|

1.0

|

5.4

|

|

41905A

|

41905AZ

|

19±0.18

|

7.0

|

7.2

|

0.5

|

5.4

|

|

42520A

|

42520AZ

|

25±0.25

|

80

|

82

|

1.0

|

8.2

|

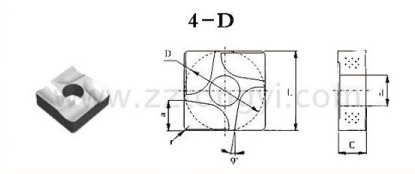

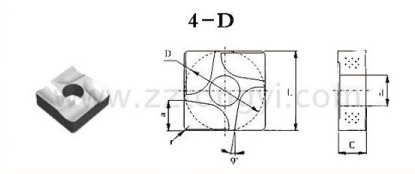

4-D

|

Model

|

Dimension

|

|

Right

|

Left

|

D=L

|

C±0.13

|

D±0.13

|

r

|

a≈

|

|

41610D6

|

41610D6Z

|

16±0.18

|

5.5

|

6.2

|

1.0

|

6

|

|

41920D7

|

41920D7Z

|

19±0.18

|

7.0

|

4.2

|

2.0

|

7

|

|

42220D8

|

42220D8Z

|

22±0.25

|

8.5

|

8.2

|

2.0

|

5.4

|

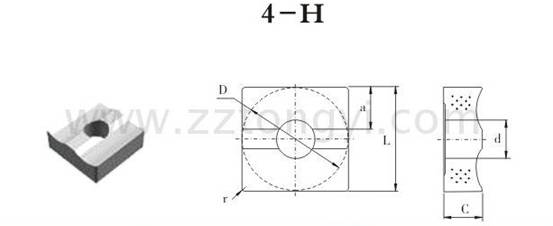

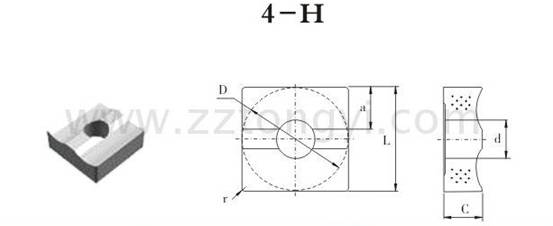

4-H

|

Model

|

Dimension

|

|

D=L

|

C±0.13

|

D±0.13

|

r

|

a≈

|

|

41005H

|

10±0.08

|

3.5

|

4.2

|

0.5

|

2.4

|

|

41305H

|

13±0.13

|

4.5

|

5.2

|

0.5

|

3.4

|

|

41605H

|

16±0.18

|

5.5

|

6.2

|

0.5

|

4.4

|

|

41605H6

|

16±0.18

|

5.5

|

6.2

|

0.5

|

6.0

|

|

41905H

|

19±0.18

|

7.0

|

7.2

|

0.5

|

5.4

|

|

41910H

|

19±0.18

|

7.0

|

7.2

|

1.0

|

5.4

|

|

41910H7

|

19±0.18

|

7.0

|

7.2

|

1.0

|

7.0

|

|

42210H8

|

22±0.25

|

8.5

|

8.2

|

1.0

|

8.0

|

|

42510H7

|

25±0.25

|

8.5

|

8.2

|

1.0

|

7.0

|

|

42510H8

|

25±0.25

|

8.5

|

8.2

|

1.0

|

8.0

|

|

42510H10

|

25±0.25

|

8.5

|

8.2

|

1.0

|

10.0

|

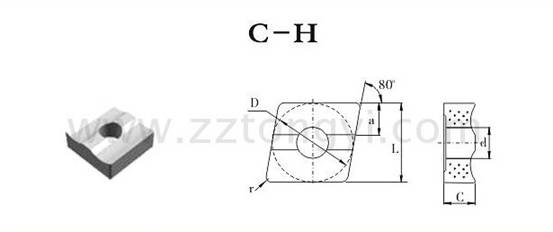

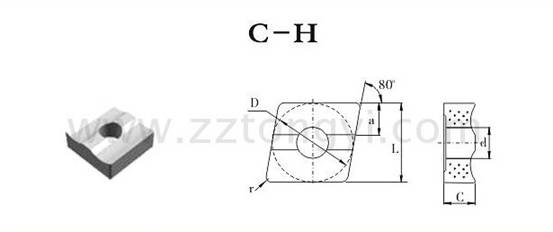

C-H

|

Model

|

Dimension

|

|

Right

|

Left

|

D=L

|

C±0.13

|

D±0.13

|

r

|

a≈

|

|

C1305H4

|

C1305H4Z

|

13±0.13

|

4.5

|

5.2

|

0.5

|

4.5

|

|

C1305H5

|

C1305H5Z

|

13±0.13

|

4.5

|

5.5

|

0.5

|

5.4

|

|

C1610H6

|

C1610H6Z

|

16±0.18

|

5.5

|

6.2

|

1.0

|

6.4

|

|

C1910H6

|

C1910H6Z

|

19±0.18

|

7.2

|

7.2

|

1.0

|

6.4

|

|

C1910H7

|

C1910H7Z

|

19±0.18

|

7.2

|

7.2

|

1.0

|

7.4

|

Established in 2002, Zhuzhou Tongyi Industry Co., Ltd. has rapidly grown into one of the most prominent supplier of tungsten carbide inserts in China. Our company provides a variety of carbide products, including tungsten carbide drill bits, carbide drawing dies, carbide rods, carbide strips, carbide anvils, carbide balls, etc. Over the years, our carbide turning blades have been exported to many countries, such as Vietnam, Indonesia, the United States, Poland, Russia, Ukraine, etc. Our products can be made in both standard and custom configurations. We have own factories, and are able to produce items according to your requirement within a short time.