Description

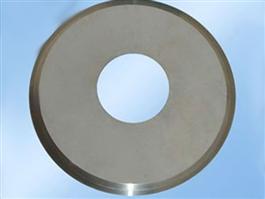

T3-A/T3-D/T3-F tungsten carbide cutting blades are driven by a high power motor and high-torque gear reduction unit or an AC vector drive. During the cutting process, the metal is released in a shearing action by the teeth as the insert turns and the feed mechanism moves the blade forward. These tungsten carbide inserts need to be ground on special machines that use diamond wheels to remove the material. We experiment with many different wheels and are now an expert at creating the correct finish on every surface of the insert. Our tungsten carbide cutting blades can be made in both standard and custom sizes.

Applications

These tungsten carbide inserts are used for cutting rubber, packaging, plastics, fiber, film, foil, mat board, capsules as well as other products. Different grades are selected for different purposes.

Advantages

1. Combining material selection, special grinding machine, EDM machine and blade knowledge, we produce premium tungsten carbide cutting blades. (EDM means Electrical Discharge Machining.)

2. A variety of tungsten carbide inserts are available in stock. For those we do not have, we are able to produce them within a short term.

3. Our company has been certified by ISO 9001: 2008. All of our products are made under quality management control.

4. Tongyi offers samples and quotations for our tungsten carbide cutting blades. We promise fast delivery.

Technical Parameters

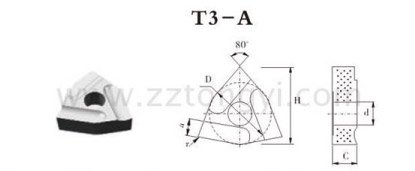

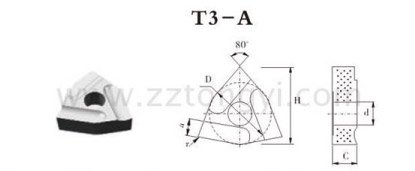

T3-A

|

Model

|

Dimension

|

|

Right

|

Left

|

H

|

D

|

C±0.13

|

d±0.13

|

r

|

a≈

|

|

T31005A

|

T31005AZ

|

13.57+0.13-0.15

|

10±0.08

|

3.5

|

4.2

|

0.5

|

2.4

|

|

T31305A

|

T31305AZ

|

16.43+0.27-0.20

|

13±0.13

|

4.5

|

5.2

|

0.5

|

3.4

|

|

T31605A

|

T31605AZ

|

20.29+0.33-0.27

|

16±0.18

|

5.5

|

6.2

|

0.5

|

4.4

|

|

T31615A

|

T31615AZ

|

19.73+0.33-0.27

|

16±0.18

|

5.5

|

6.2

|

1.5

|

4.4

|

|

T31615A5

|

T31615A5Z

|

19.73+0.33-0.27

|

16±0.18

|

5.5

|

6.2

|

1.5

|

5.4

|

|

T31905A

|

T31905AZ

|

24.13+0.37-0.27

|

19±0.18

|

7.0

|

7.2

|

0.5

|

5.4

|

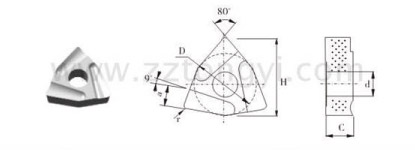

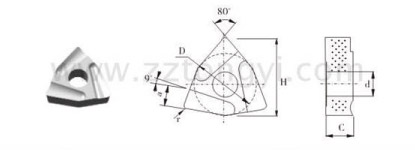

T3-D

|

Model

|

Dimension

|

|

Right

|

Left

|

H

|

D

|

C±0.13

|

d±0.13

|

r

|

a≈

|

|

T31310D5

|

T31310D5Z

|

16.15+0.27-0.20

|

13±0.13

|

4.5

|

5.2

|

1.0

|

5.5

|

|

T31610D6

|

T31610D6Z

|

20.01+0.33-0.27

|

16±0.18

|

5.5

|

6.2

|

1.0

|

6.5

|

|

T31920D7

|

T31920D7Z

|

23.31+0.37-0.27

|

19±0.18

|

7.0

|

7.2

|

2.0

|

7.4

|

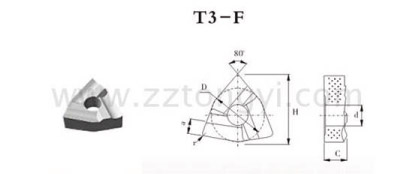

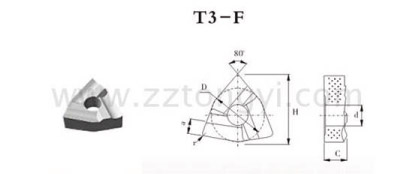

T3-F

|

Model

|

Dimension

|

|

Right

|

Left

|

H

|

D

|

C±0.13

|

d±0.13

|

r

|

a≈

|

|

T31005F

|

T31005FZ

|

12.57+0.23-0.15

|

10±0.08

|

3.5

|

4.2

|

0.5

|

2.4

|

|

T31305F

|

T31305FZ

|

16.43+0.23-0.15

|

13±0.13

|

4.5

|

5.2

|

0.5

|

3.4

|

|

T31605F

|

T31605FZ

|

20.29+0.23-0.15

|

16±0.18

|

5.5

|

6.2

|

0.5

|

4.4

|

|

T31905F

|

T31905FZ

|

24.13+0.23-0.15

|

19±0.18

|

7.0

|

7.2

|

0.5

|

5.4

|

Established in 2002, Zhuzhou Tongyi Industry Co., Ltd. is a professional manufacturer of tungsten carbide cutting blades in China. Our carbide products are widely recognized by many major manufacturers. Typical products include tungsten carbide drill bits, carbide rods, carbide blanks, carbide anvils, carbide drawing dies, tungsten carbide inserts, carbide disc cutter, carbide brazed tips, etc. Our products have been exported to many countries, such as Vietnam, Philippines, Indonesia, Poland, Russia, the United States, etc. Our company is able to produce custom tungsten carbide cutting blades of various grades within a short time.